Composite GFRP

Sustainable Solutions

GFRP production generates

60% to 70% less CO2 than steel rebar

Stronger

than steel

Cost-Saving

Production, Transport, Installation

Eco-Friendly

Longer lifetime

Sustainable

Low CO2 Emissions

What are GFRP Rebars?

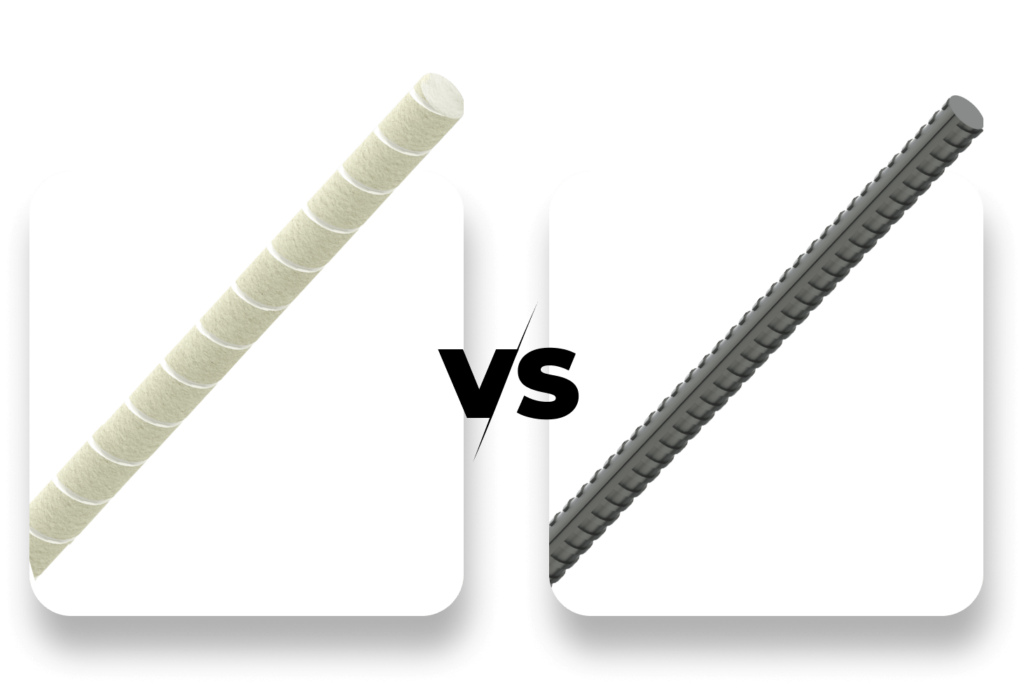

Glass fiber reinforced polymer (GFRP) rebar is an alternative reinforcing bar to traditional steel rebar.

Unlike traditional steel rebar, which is made of carbon steel, GFRP rebar is composed of high-strength glass fibers embedded in a polymer resin matrix.

This material offers several advantages over steel rebar, including corrosion resistance, high strength-to-weight ratio, electromagnetic neutrality, and non-conductivity.

- Non-Corrosive

- Stronger than Steel

- Light weight

- Less concrete coverage needed

- Less concrete coverage needed

- Longer lifespan than steel

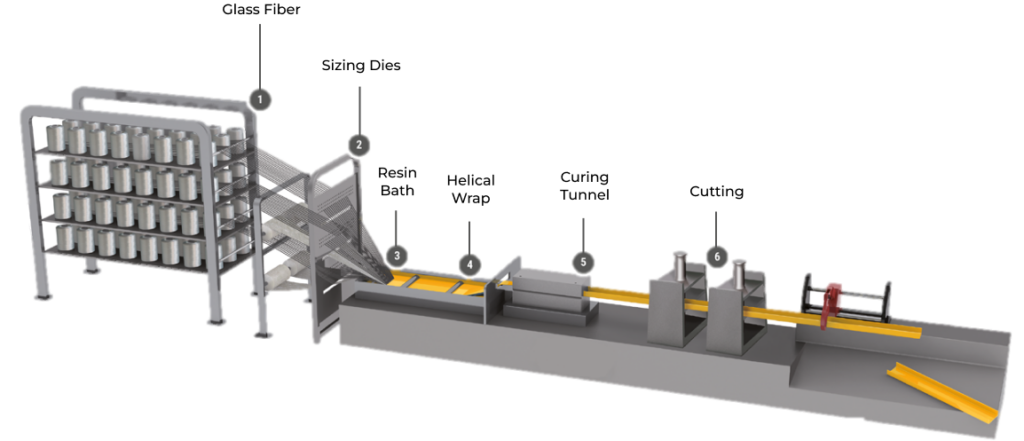

How is GFRP made?

Fiber

Glass

Carbon

Resin

Poly-ester

Carbon

Epoxy

Properties and Specifications of GFRP Ground Anchors

Temporary GFRP ground anchors are 25% lighter than conventional steel strand anchors while exhibiting twice the strength. They can be installed using the same construction methods as their steel counterparts and maintain similar diameters and strand quantities.

These GFRP ground anchors possess safe working loads of up to 150 kilonewtons and are resistant to both acidic and alkali soil conditions.

Easy removal and minimal risk

Crucially, temporary GFRP ground anchors can be easily cut and removed using piling, excavation, and tunnel boring machines without the risk of damage or program delays.

This feature provides convenience for developers and contractors, streamlining construction processes and minimizing potential setbacks or program delays.

Using GFRP in Tunneling projects

In tunneling, soft-eye applications refer to the use of GFRP (Glass Fiber Reinforced Polymer) elements, such as bars or tendons, to reinforce and support the excavation face of a tunnel during construction. GFRP bars are typically installed in a radial pattern around the periphery of the tunnel face and anchored into the surrounding ground.

Additionally, GFRP bars are generally softer and less abrasive than steel reinforcement, making them easier to cut with tunnel boring machines (TBMs) equipped with cutting tools. This property reduces wear and tear on the TBM’s cutting tools, leading to lower maintenance costs and minimizing the risk of damage to the equipment.

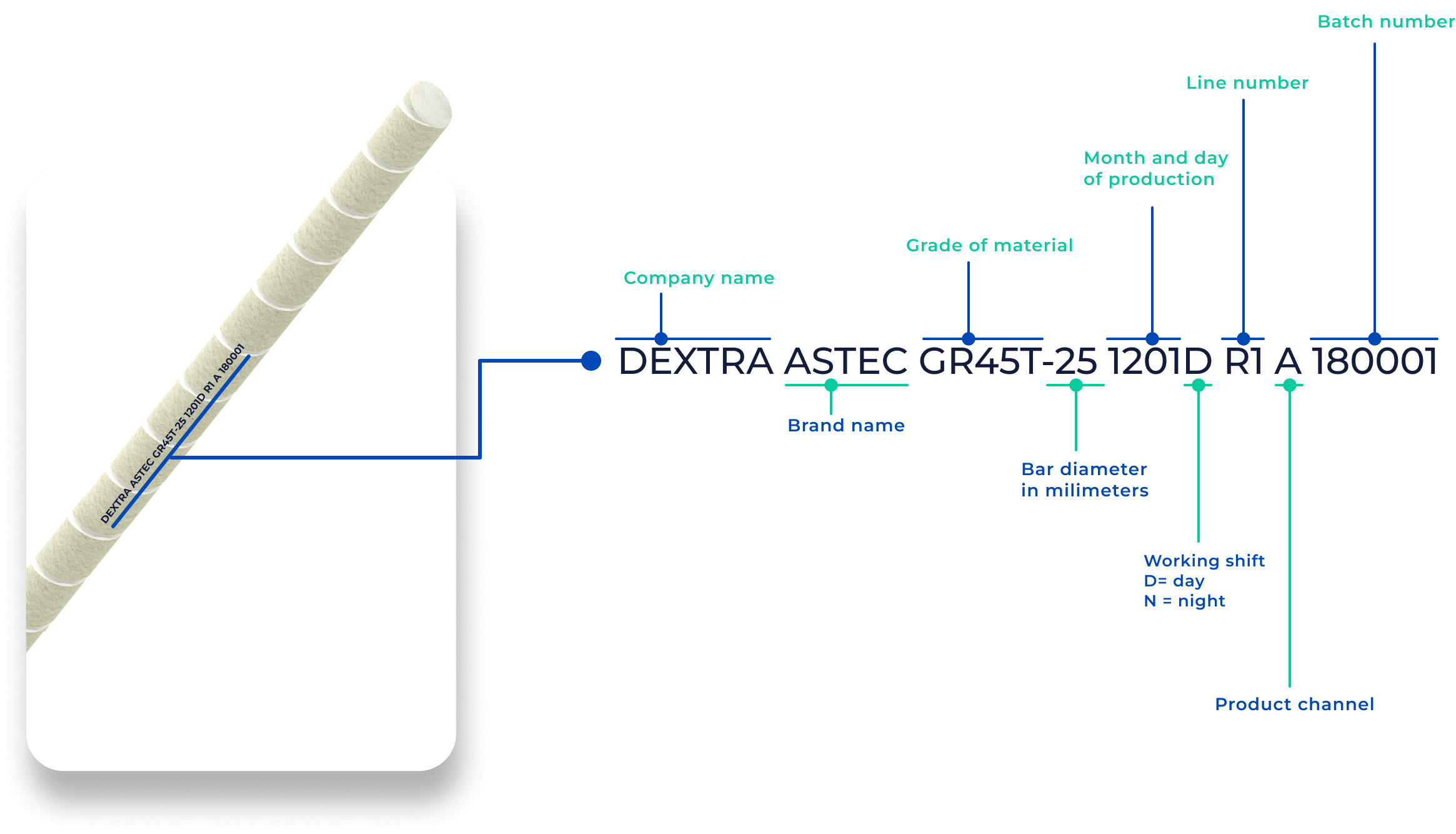

Product Traceability

Each product is individually marked

following certain syntax, ensuring full traceability.