High-performance Post-Tensioning solution

Dextra’s Post Tensioning Bar Systems can be used for a variety of temporary and permanent construction applications. Typical permanent applications include the connection of girders and piers in segmental bridge construction. Temporary uses include heavy lifting, pre-loading, stitching and anchoring of steel frame supports.

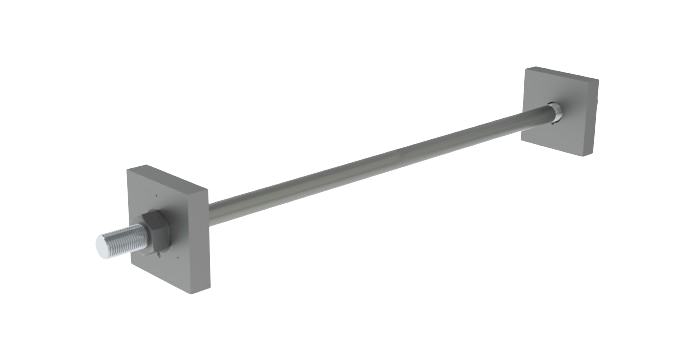

Dextra PT range is divided in two major type of bars. This page focuses on the PT Bar systems using smooth high performance carbon steel bars with threaded ends, which are prepared to length as per project requirements.

Product features

- Standard range or 20 diameters from M30 (28mm) to M103 (100mm).

- 3 standard grades available: Grade 1030, Grade 1080 and Grade 1200.

- ISO-metric threads based on ISO 262. Other thread profiles available upon request.

- Standard accessories include nuts and plates (in swivel or flat configuration), as well as couplers to achieve longer length.

- Corrosion systems also available by Dextra.

Wide range

2 designs. 2 grades. 17 diameters.

Find the right match for your

structure.

Engineering support

Dextra teams support the drafting

of your system

Full Traceability

Full identification from drawing to

individual part labeling.

Benefits of Post Tensioning Smooth bar systems

- Rolled threads (obtained by cold plastic deformation of the metal between dies) to achieve high fatigue performance.

- High impact strength performance.

- High impact resistance.

- Full range of accessories.

- Design support from Dextra team.

Related Projects

Related solutions

Tension Rods are aesthetic and highly-performing bar systems working in tension, usually for the cross-bracing of roof or façade structures.

Expertise

At every moment of your customer journey, Dextra teams dedicate themselves to the production of smart construction solutions that allow our customers to reach higher productivity and safety levels on their construction sites.

Dextra holds physical stocks on several continents, complemented in each country by the local inventories of our distributors. With this extended network, Dextra makes sure our products are always at reach no matter where our partners are.

For solutions that require to be customized, Dextra can also go beyond our standard delivery times and offer accelerated delivery schemes. Consult us for more information.

From 3 major industrial sites located in Bangkok (Thailand), Guangzhou (China), and Pune (India), Dextra completely owns its manufacturing facilities and processes. This allows us to have complete control over the timing of our operations and the quality of the solutions produced.

An independently accredited material testing laboratory, accredited to ISO-IEC17025, is located at Dextra’s main Bangkok factory, allowing the testing of material and products.

Dextra aims to supply products that exceed the most demanding international technical approvals and it is our goal to create maximum customer satisfaction by complying with our clients’ needs and specified requirements.